We at ESR Forged Wheels continue to be dedicated to producing not only wheels but also a lifestyle that reflects a passion for creativity and a desire for delivering the finest wheels. Performance and longevity is the hallmark of a great wheel. That is why we place a heavy emphasis on precision designing, precise engineering, and expert craftsmanship. Aiming to achieve the highest quality wheels in our industry.

MADE IN THE USA.

STARTING FROM SCRATCH.

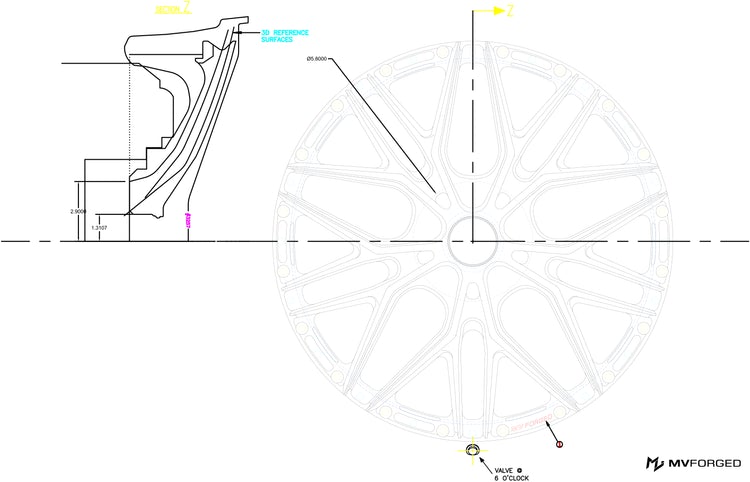

ENGINEERING | FEA TESTING

Step 1:

Each set of ESR Wheels are meticulously designed, engineered, and crafted in our Southern California Facility. Our team at ESR Wheels with over 70 years of combined forged wheel experience allows us to have full control over the quality of our process. Each order goes through Finite Element Analysis (FEA) testing to ensure the most optimal combination of lightweight, durability, and strength.

Step 2:

6061 T6 AERO SPACE FORGED

RAW FORGINGS.

By making the wheel a forged one piece we have eliminated any possibility of porosity. The world’s leading aircraft manufacturers use one-piece forgings for superior performance in critical structural applications. App Forged Wheels uses the same process, combined with over 50 years experience manufacturing aerospace and commercial forged products, to produce aluminum wheels. The result is a high strength, lightweight wheel with no porosity and no welded joints.

The forging process uses high pressure and temperature to change the non-directional grain structure of the cast aluminum starting material to the high integrity multi-directional grain structure of forgings. The aluminum remains solid throughout the process as the forging dies come together and change the shape of the round cast bar to the cylindrical shape of a wheel. The forged wheel blank is then placed in a custom built spin-forging machine to spin out and forge the rim section. The resulting radial grain direction places the highest material strength in the same direction as the operating loads. The result is “premium strength”.

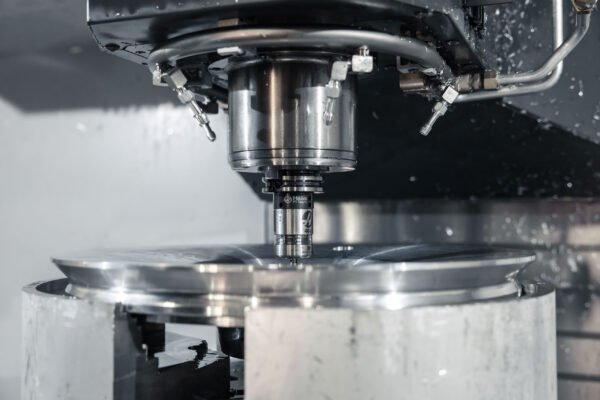

LATHE TURNING

CONCAVITY.

Step 3:

The key step in manufacturing a forged wheel is lathe turning. The raw forging is lathe-turned from the front and rear, creating a profile that maximizes concavity. In this step over 70% of the original material is removed, utilizing the most weight reduction.

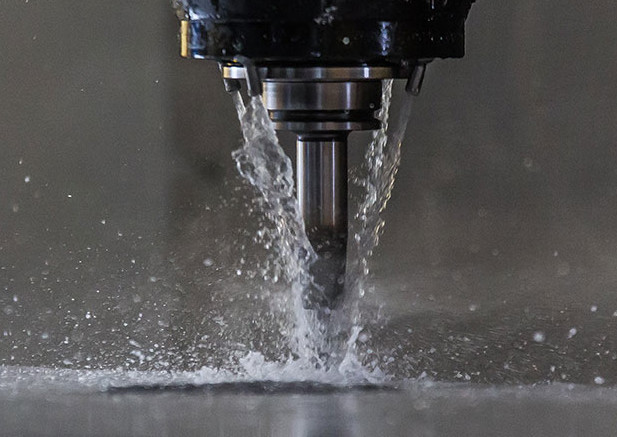

TOOLING & FLUIDS

ACCURACY.

Anti Vibration Tools – In order to create tighter machining tolerances and the smoothest finishes. We chose to use Sandvik ®, a German manufacture and leaders of the finest lathe tools in the industry. Utilizing their unique Silent Tools ™ Anti-Vibration Technology, this technology enables our production to eliminate vibrations that can cause bad surface texture, and insufficient accuracy.

The Wireless Intuitive Probing System – (WIPS) guides the operator through the job set-up process and helps reduce setup time by allowing the operator to multitask while the automatic probing routines are running. WIPS ensures that tools and parts are maintained within tolerance throughout the production process.

Coolant – At ESR Forged we decided to use the best coolant in our industry; Blaser®. A Swiss Lube company manufactured in Switzerland for the last 80 years. By optimizing the machining process and using Blaser® cutting fluid to enable higher speeds, feed, machining rates, and spotless surfaces.

QUALITY CONTROL.

Step 4:

Each center after turning is remeasured and goes through a quality control check list to ensure each part meets our standards and tolerances before the milling process begins.

WHERE DESIGN COMES TO LIFE

MILLING.

Step 5:

After the milling process is completed, each section of raw milled aluminum needs to go through many stages of Hand Filing, Deburring, Buffing and Ceramic Bead High-Luster Polishing before it is ready for its ultimate finish. This is a vital stage for our craftsmen to prep each wheel before its coating. After each wheel is filed and sculpted the wheels go through a detailed check list with zero compromises.

WEIGHT REDUCTION.

All designs now feature Scallop Undercutting which has reduced the overall Weight and Unsprung Mass of every wheel we manufacture. Scalloping the sides of the spokes creates an “I-Beam” cross-section through its length, maximizing its strength to weight. Each design has also been standardized with Through-Hub Pockets between the lug holes that allow for more efficient heat dissipation and reduce unsprung mass/weight on the wheel hub. Designs are offered under 5 unique build configurations that share and individualize newly developed details.

DEBURRING | CERAMIC POLISH | BRUSH

PREP.

Step 6:

The most attentive yet time consuming part of the finishing process is brushing and polishing. Offered as upgraded options in every ESR Forged wheel collection, brushed wheels reveal the beautiful details in the forged aluminum grain while touch-less high-luster ceramic polishing creates a mirror-like finish.

COLOR.

Step 7:

The most rewarding part of the manufacturing process is the finish stage. That is why we confidently hand chose vendors from Brisbane Australia, Tokyo Japan and Hamburg Germany. ESR Forged premium finish line offers a brushed or polished base paired with transparent powder coats to reveal the beauty and details in the design. At ESR Wheels we are always learning new ways in achieving the utmost beautiful finishes in our industry.

Each component of the wheel is offered with a Gloss, Satin or Texture finish of your choice.

ASSEMBLY.

Step 8:

The assembly stage is one of the most critical stages in the manufacturing stage. First step is to check the run-out of every wheel to guarantee the wheels are balanced to eliminate vibrations and wobbling. We chose to use Digital Snap-On® Torque Wrenches vs generic torque wrenches. One of the advantages is that it can more precisely control the amount of torque that’s applied to a bolt without losing any torque capacity.

No wheel will pass our quality control unless it falls below 0.010″ (10 thousandths of an inch). While industry standard complies within 0.030″ (30 thousandths of an inch), we are consistently testing run outs within 0.007″ (7 thousandths of an inch) to ensure no wheel vibrates at high speeds.

TORQUE SPEC.

Every year or 5,000 cycles we will calibrate our wrenches to ensure accuracy and safety. After each bolt and nut is torqued we mark them and have our expert assemblers sign off the wheels for packaging.

ESRWHEELS - 350 Ranger Ave Ste A Brea, CA 92821

ESRWHEELS - 350 Ranger Ave Ste A Brea, CA 92821